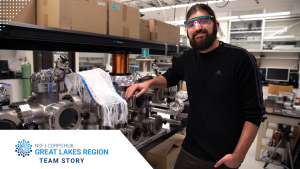

Brian Iezzi sat in his small Ann Arbor apartment pondering a question: why is so little of the world’s textiles and fabrics recycled? Part of the challenge lies within the fabrics’ composition; they cannot be recycled if what they are made of is unknown. This led the University of Michigan PhD alumni, Brian Iezzi, to pull from his existing knowledge of fabrics and science to create a new solution, where a barcode of information is embedded in the threads of the fabric. His innovation journey would lead to the creation of Fibarcode, a journey through the NSF I-Corps program, and around the world.

Creating a Sustainable Textile Industry with Fibarcode

For recyclers to process materials, they need to know what it is made of. Unlike glass bottles or milk jugs, fabrics’ compositions are diverse and complex. What fabric is made of is usually on the tag, but that is often lost by the time it makes it to the recycler. This is where Fibarcode’s unique solution comes into play. The technology, based on research from Dr. Max Shtein’s Lab at the University of Michigan, enables engineered fibers with a unique identity to be interwoven directly into the textile, allowing them to behave like a barcode. This interwoven fabric barcode can then be read by an optical scanner. This way the composition of the fabric can always be determined by a recycler, enabling more effective sorting for processing. Iezzi hopes that Fibarcode’s technology will enable more textiles to be recycled. This can allow for a more sustainable industry, with less waste.

The ‘Fibarcode’ is scanned. Photo: Marcin Szczepanski/Michigan Engineering

NSF I-Corps

During his time working with the Shtein Lab at the University of Michigan College of Engineering, Iezzi and the team got accepted into the prestigious National Science Foundation I-Corps Teams program. The immersive 7-week program is designed to avoid building a product that no one wants; the number one reason startups fail. Throughout the program, teams conduct over 100 customer discovery interviews.

“It was an eye-opening experience for me. I realized we needed to find a value proposition for everyone in the supply chain to make a product like Fibarcode work. Recyclers loved the idea, but what about the brand and manufacturer? They would be paying to integrate the product so they need to get value as well.” – Brian Iezzi

As part of the NSF I-Corps program, Iezzi and the team were awarded $50,000 to use for customer discovery. He used the funds to travel around the world to learn more about the textile industry:

“Because of the I-Corps program, I got to travel all over the world. I visited garment manufacturers and resellers in Nairobi and Addis Ababa to learn more about their efforts in recycling cut scraps and local secondhand markets. I also traveled to the city of Milan, Italy, for the largest textile manufacturing conference in the world. It only happens once every four years. People call it the World Cup of textile fairs. I had the opportunity to meet the entire value chain for the textile industry.”

Brian (right) had the opportunity to visit leaders in textile recycling in Nairobi, Kenya. This included Liz Muturi (left), formerly of UPSET Textiles.

The Innovator Advisor Community and Mentoring I-Corps

In an effort to grow his network, Fibarcode and Iezzi participated in the Great Lakes I-Corps Hub’s Innovator Advisor Community (IAC) fellowship program. The program coaches I-Corps graduates on how to communicate their technology and connect with industry experts and the regional ecosystem to advance their technology development.

“The IAC has been super helpful. There have been a few times when I need to practice and prepare a pitch for Fibarcode. The team brought together a panel of experts to provide focused feedback”

Even with his busy schedule growing his company, Iezzi has continued to be involved in the innovation ecosystem. Over the past year, he has been a peer mentor for the University of Michigan’s Local I-Corps course. As a mentor, he has been helping participants through the program by giving practical advice and best practices for customer discovery.

“It’s been very rewarding mentoring the I-Corps teams. I was in their shoes over a year ago. I’m not an expert, but after you’ve done over 100 customer discovery interviews, you learn little tips and tricks that can help you get better information and build relationships. I’ve been able to share these tips with others and help them on their journey.”

The virtual I-Corps Program provides an introduction to customer discovery.

The Future

For Fibarcode and Iezzi, the future is filled with opportunity. Supported by grants such as the US Department of Energy LEEP fellowship, Iezzi hopes to develop a pilot that demonstrates Fibarcode’s technology to future investors. Helped by the insights gained from the I-Corps program and support from various grants, Fibarcode is poised to make the world a more sustainable place one garment at a time.

Interested in Fibarcode’s technology? They are looking for industry collaborators! Inquire via their website: https://www.fibarcode.com

Collaborators on the Fibarcode project include Dr. Brian Iezzi, University of Michigan professors Dr. Max Shtein, Dr. Alanson Sample, and Dr. Sean Ahlquist, and graduate students Yash Dadeech and Raghav Varshney.

Learn more about I-Corps here: https://greatlakesicorps.org/programs/

Images courtesy of Michigan Engineering

Quotes Edited for Clarity

Written by Chris Eakin

NSF I-Corps Hub: Great Lakes Region, 2024